DOWNSTREAM PLASTIC EXTRUSION MACHINES

Combination Pullers/Cutters

These machines process and finish extruded plastic products. The pullers pull the extrusion to ensure accurate sizing and positioning. The cutting element then cuts the extrusion into predetermined lengths.

Servo-Driven Cutters

Servo-driven machinery is automated, precise, and capable of providing extremely fast and accurate cuts. The machinery interprets directions from a design file and implements the steps. Servo-driven cutters cut lengths of extruded plastic into manageable pieces or the final product sizes.

Belt Pullers

Belt pullers pull extrusions, keeping them straight and properly aligned with the extrusion machinery without stretching or damaging the product. Then they draw the extrusions through the subsequent sizing and cooling tanks as the shapes set.

Sizing and Cooling Tanks

Extruded parts shrink and have the potential to deform in a poorly managed cooling process. Sizing and cooling tanks provide control during the shrinkage stage by quickly and consistently removing heat from in-process extrusions. This results in consistent products that have the right size and dimensionality.

Pipe and Profile Saws

These saws cut plastic extrusions to their final product lengths. They need to be accurate and fast-moving to avoid bottlenecks in the production line.

Auxiliary Equipment

We offer two key sets of auxiliary equipment: post extrusion take-away conveyors and dump tables.

Wheel Pullers and Embossers

Like standard pullers, wheel pullers can grip and handle extrusions throughout the embossing process. Rigid extrusions work best with wheel pullers because the equipment provides a stronger grip with more traction. Embossers allow users to create an aesthetic or functional design on the extruded profiles.

Coiling Machines

Coiling machines coil and organize long lengths of flexible extruded pipes or tubing without damaging the product or putting it under strain. Coiling is an industry-standard method for storing and shipping long lengths of extrusions. Some products, such as small cables and insulated conductors, also should be coiled and bound for safe transport.

At RDN Manufacturing, we specialize in post-extrusion equipment manufacturing. Our equipment helps plastic extruders to produce high-quality and cost-effective extruded plastic goods. We design, refine, and manufacture industrial equipment that can simplify and streamline your facility’s downstream plastic extrusion processes. Every machine is built for decreased downtime, easy maintenance and operation, and enhanced production efficiency. Our catalog of downstream plastic extrusion machines includes:

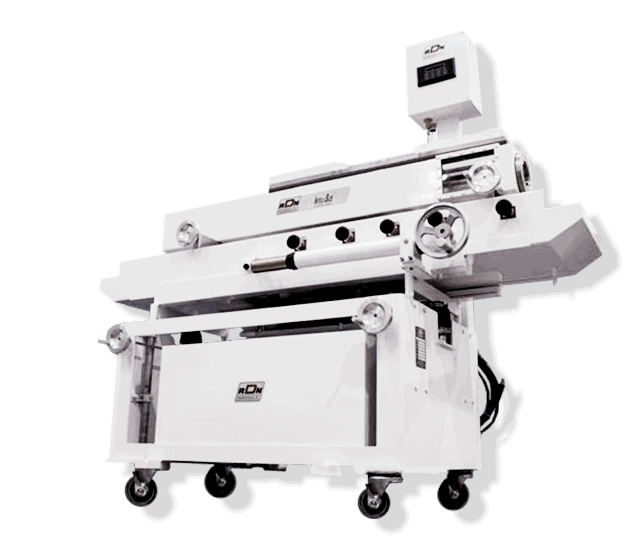

Combination Pullers/Cutters

These machines process and finish extruded plastic products. The pullers pull the extrusion to ensure accurate sizing and positioning. The cutting element then cuts the extrusion into predetermined lengths.

Features and Benefits

This compact machine is ideal for cutting rods, pipes, and tubes. Our machines can handle ¼-inch to 6-inch out diameter (OD) tubing and profiles while providing 200-1,000 cuts per minute.

Servo-Driven Cutters

Servo-driven machinery is automated, precise, and capable of providing extremely fast and accurate cuts. The machinery interprets directions from a design file and implements the steps. Servo-driven cutters cut lengths of extruded plastic into manageable pieces or the final product sizes.

Features and Benefits

Our smart servo-driven systems are efficient and reliable so your team can increase production while maintaining or improving product quality. Some of the unique features of our servo-driven cutters include:

- Quick blade-change systems

- High torque ratings

- Between 200-1,000 cuts per minute with rotary blades

Belt Pullers

Belt pullers pull extrusions, keeping them straight and properly aligned with the extrusion machinery without stretching or damaging the product. Then they draw the extrusions through the subsequent sizing and cooling tanks as the shapes set.

Features and Benefits

High-quality belt pullers help ensure that extruded products remain consistent along the length of the extrusion. Our units also protect operators by enclosing the belt guards. Models from RDN Manufacturing include these size options:

- Belt contact length: 12-60″

- Belt width: 2-6″

- Maximum belt opening: 2-12″

Sizing and Cooling Tanks

Extruded parts shrink and have the potential to deform in a poorly managed cooling process. Sizing and cooling tanks provide control during the shrinkage stage by quickly and consistently removing heat from in-process extrusions. This results in consistent products that have the right size and dimensionality.

Features and Benefits

Having the right sizing and cooling tanks can ensure:

- Consistent product quality, even at high volumes or production speeds

- Accuracy, even with flexible PVC, urethane, and other tacky or flexible materials

- Easy-to-use interfaces and digital readouts, so operators can manage the temperature and vacuum settings of the tanks

Pipe and Profile Saws

These saws cut plastic extrusions to their final product lengths. They need to be accurate and fast-moving to avoid bottlenecks in the production line.

Features and Benefits

Our pipe and profile saw equipment has saw blade options ranging from 10-24 inches in size for a cut size capability ranging from 2-20 inches. We also build our saw equipment with a unique clamp function to streamline precision cuts.

Auxiliary Equipment

We offer two key sets of auxiliary equipment: post extrusion take-away conveyors and dump tables.

- Post-extrusion take-away conveyors. Small tubing projects or setups can use these conveyor systems during cutting operations. The knife sends air across the conveyor to move components without direct handling and provides an air ejection option. Our models offer 115/1/60 line voltage through a variable speed DC motor, as well as an SCR to control belt speed.

- Dump tables for plastic profile extrusion. We provide a diverse range of table sizes for operations that handle rigid profile extrusions.

Wheel Pullers and Embossers

Like standard pullers, wheel pullers can grip and handle extrusions throughout the embossing process. Rigid extrusions work best with wheel pullers because the equipment provides a stronger grip with more traction. Embossers allow users to create an aesthetic or functional design on the extruded profiles.

Features and Benefits

Our wheel pullers and embossers have heavy steel plates for strong control. We create models with either two or four shafts, and each machine can handle variable widths and shapes.

Coiling Machines

Coiling machines coil and organize long lengths of flexible extruded pipes or tubing without damaging the product or putting it under strain. Coiling is an industry-standard method for storing and shipping long lengths of extrusions. Some products, such as small cables and insulated conductors, also should be coiled and bound for safe transport.

Features and Benefits

Our coiling machines are built for precision with:

- Dual axis spindle and traverser TENV A.C. BRUSHLESS Servo Drive Motors

- Product traverse guides mounted on precision linear bearings for continuous product control

- In-machine measuring tools that can display English or metric units for a given order